INCONEL alloy 718, conventionally hot-rolled (IN_C_2)

The elastic properties (Young's modulus, shear modulus) of Ni-based alloy Inconel IN718 were investigated between room temperature and 800 °C in an additively manufactured variant (laser powder bed fusion, PBF‑LB/M) and from a conventional process route (hot rolled bar). The moduli were determined using the dynamic resonance method. The data set includes information on processing parameters, heat treatments, grain size, specimen dimensions and weight, Young’s and shear modulus as well as their measurement uncertainty.

The dataset was generated in an accredited testing lab using calibrated measuring equipment. The calibrations meet the requirements of the test procedure and are metrologically traceable. The dataset was audited as BAM reference data. The dataset was made available under the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/legalcode).

Further information on data and data acquisition, analysis, and experimental details are given in “Elastic modulus data for additively and conventionally manufactured variants of Ti‑6Al‑4V, IN718 and AISI 316L” published in Scientific Data.

- Measurement of Young´s modulus and shear modulus: Elastotron 2000 (HTM Reetz, Berlin, Germany)

- T = temperature

- m = mass

- ff(e) = fundamental resonance frequency of the bar in flexure (edge wise)

- ff(f) = fundamental resonance frequency of the bar in flexure (flat wise)

- ft = fundamental resonance frequency of the bar in torsion

Herstellungsverfahren und Ausgangsmaterialien

Physikalische Eigenschaften

| Name | Wert | Bemerkung | Messverfahren und -bedingungen |

|---|---|---|---|

| (mittlere) Korngröße | 0.006 mm | EBSD | |

| Abmessung (Länge) | 99.92 mm | T = 24 °C | |

| Abmessung (Länge) | 100.03 mm | T = 100 °C | |

| Abmessung (Länge) | 100.17 mm | T = 200 °C | |

| Abmessung (Länge) | 100.31 mm | T = 300 °C | |

| Abmessung (Länge) | 100.46 mm | T = 400 °C | |

| Abmessung (Länge) | 100.62 mm | T = 500 °C | |

| Abmessung (Länge) | 100.8 mm | T = 600 °C | |

| Abmessung (Länge) | 100.91 mm | T = 650 °C | |

| Abmessung (Länge) | 101.03 mm | T = 700 °C | |

| Abmessung (Länge) | 101.13 mm | T = 750 °C | |

| Abmessung (Länge) | 101.24 mm | T = 800 °C | |

| Abmessung (Breite) | 9.003 mm | T = 24 °C | |

| Abmessung (Breite) | 9.013 mm | T = 100 °C | |

| Abmessung (Breite) | 9.025 mm | T = 200 °C | |

| Abmessung (Breite) | 9.038 mm | T = 300 °C | |

| Abmessung (Breite) | 9.052 mm | T = 400 °C | |

| Abmessung (Breite) | 9.066 mm | T = 500 °C | |

| Abmessung (Breite) | 9.082 mm | T = 600 °C | |

| Abmessung (Breite) | 9.092 mm | T = 650 °C | |

| Abmessung (Breite) | 9.103 mm | T = 700 °C | |

| Abmessung (Breite) | 9.112 mm | T = 750 °C | |

| Abmessung (Breite) | 9.122 mm | T = 800 °C | |

| Abmessung (Tiefe) | 3 mm | T = 24 °C | |

| Abmessung (Tiefe) | 3.003 mm | T = 100 °C | |

| Abmessung (Tiefe) | 3.007 mm | T = 200 °C | |

| Abmessung (Tiefe) | 3.012 mm | T = 300 °C | |

| Abmessung (Tiefe) | 3.016 mm | T = 400 °C | |

| Abmessung (Tiefe) | 3.021 mm | T = 500 °C | |

| Abmessung (Tiefe) | 3.026 mm | T = 600 °C | |

| Abmessung (Tiefe) | 3.03 mm | T = 650 °C | |

| Abmessung (Tiefe) | 3.033 mm | T = 700 °C | |

| Abmessung (Tiefe) | 3.036 mm | T = 750 °C | |

| Abmessung (Tiefe) | 3.04 mm | T = 800 °C | |

| Dichte | 8.255 g/cm³ | T = 24 °C | |

| 8.228 g/cm³ | T = 100 °C | ||

| 8.194 g/cm³ | T = 200 °C | ||

| 8.159 g/cm³ | T = 300 °C | ||

| 8.122 g/cm³ | T = 400 °C | ||

| 8.083 g/cm³ | T = 500 °C | ||

| 8.041 g/cm³ | T = 600 °C | ||

| 8.014 g/cm³ | T = 650 °C | ||

| 7.986 g/cm³ | T = 700 °C | ||

| 7.962 g/cm³ | T = 750 °C | ||

| 7.937 g/cm³ | T = 800 °C | ||

| Mechanische Eigenschaften | |||

| Schubmodul | 79 GPa | ft = 8717.0 Hz | ASTM E 1875, T = 24 °C |

| 77 GPa | ft = 8602.0 Hz | ASTM E 1875, T = 100 °C | |

| 74 GPa | ft = 8454.0 Hz | ASTM E 1875, T = 200 °C | |

| 72 GPa | ft = 8323.0 Hz | ASTM E 1875, T = 300 °C | |

| 69 GPa | ft = 8178.0 Hz | ASTM E 1875, T = 400 °C | |

| 67 GPa | ft = 8043.0 Hz | ASTM E 1875, T = 500 °C | |

| 63 GPa | ft = 7854.0 Hz | ASTM E 1875, T = 600 °C | |

| 62 GPa | ft = 7755.0 Hz | ASTM E 1875, T = 650 °C | |

| 60 GPa | ft = 7632.0 Hz | ASTM E 1875, T = 700 °C | |

| 58 GPa | ft = 7499.0 Hz | ASTM E 1875, T = 750 °C | |

| 56 GPa | ft = 7366.0 Hz | ASTM E 1875, T = 800 °C | |

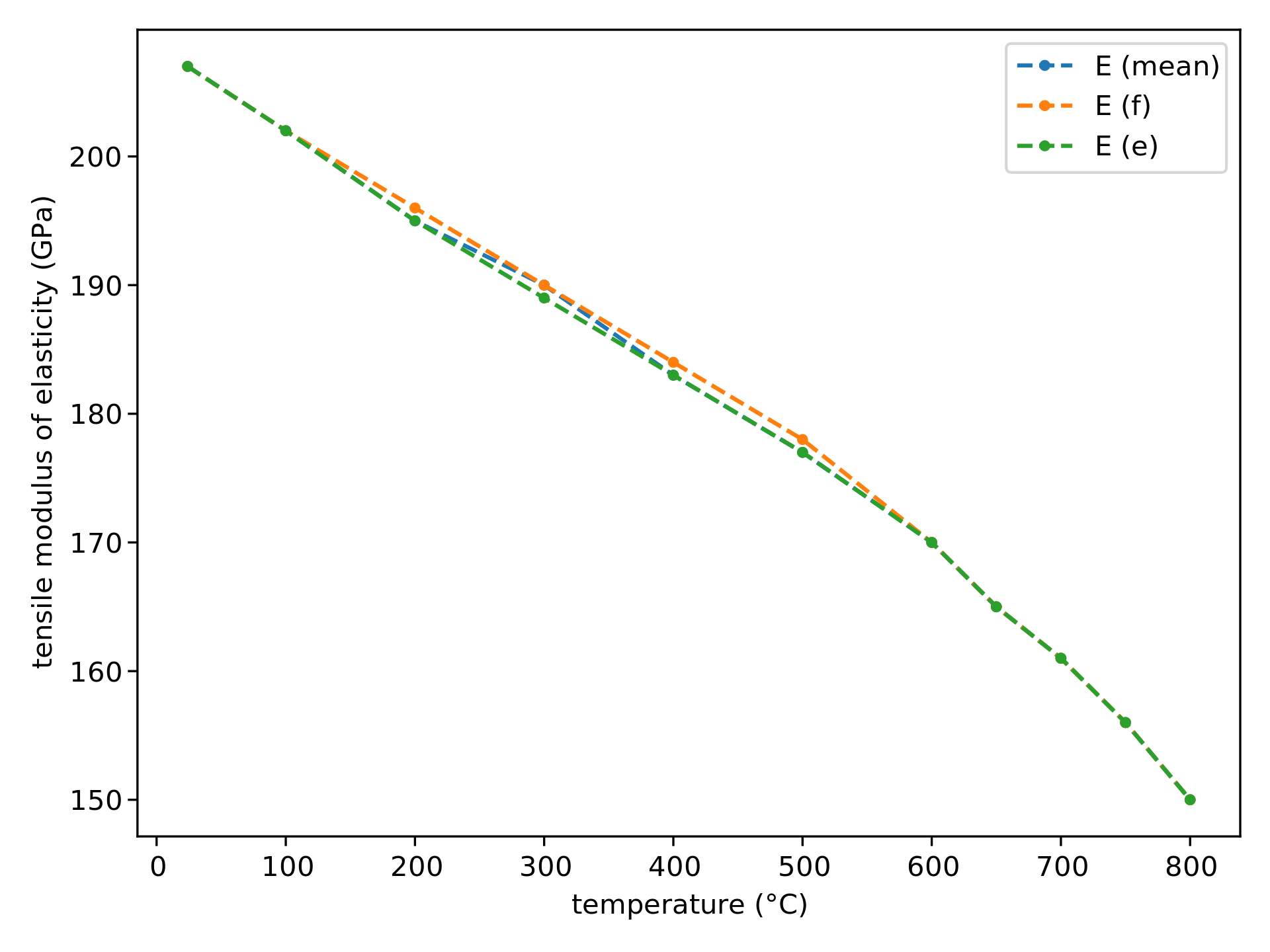

| Zug-Elastizitätsmodul | 207 GPa | mean | ASTM E 1875, T = 24 °C |

| 207 GPa | flat-wise in the thickness direction, ff(f) = 1543.0 Hz | ASTM E 1875, T = 24 °C | |

| 207 GPa | edge-wise in the width direction, ff(e) = 4512.0 Hz | ASTM E 1875, T = 24 °C | |

| 202 GPa | mean | ASTM E 1875, T = 100 °C | |

| 202 GPa | flat-wise in the thickness direction, ff(f) = 1525.0 Hz | ASTM E 1875, T = 100 °C | |

| 202 GPa | edge-wise in the width direction, ff(e) = 4459.0 Hz | ASTM E 1875, T = 100 °C | |

| 195 GPa | mean | ASTM E 1875, T = 200 °C | |

| 196 GPa | flat-wise in the thickness direction, ff(f) = 1501.0 Hz | ASTM E 1875, T = 200 °C | |

| 195 GPa | edge-wise in the width direction, ff(e) = 4388.0 Hz | ASTM E 1875, T = 200 °C | |

| 190 GPa | mean | ASTM E 1875, T = 300 °C | |

| 190 GPa | flat-wise in the thickness direction, ff(f) = 1480.0 Hz | ASTM E 1875, T = 300 °C | |

| 189 GPa | edge-wise in the width direction, ff(e) = 4323.0 Hz | ASTM E 1875, T = 300 °C | |

| 183 GPa | mean | ASTM E 1875, T = 400 °C | |

| 184 GPa | flat-wise in the thickness direction, ff(f) = 1456.0 Hz | ASTM E 1875, T = 400 °C | |

| 183 GPa | edge-wise in the width direction, ff(e) = 4255.0 Hz | ASTM E 1875, T = 400 °C | |

| 177 GPa | mean | ASTM E 1875, T = 500 °C | |

| 178 GPa | flat-wise in the thickness direction, ff(f) = 1433.0 Hz | ASTM E 1875, T = 500 °C | |

| 177 GPa | edge-wise in the width direction, ff(e) = 4189.0 Hz | ASTM E 1875, T = 500 °C | |

| 170 GPa | mean | ASTM E 1875, T = 600 °C | |

| 170 GPa | flat-wise in the thickness direction, ff(f) = 1403.0 Hz | ASTM E 1875, T = 600 °C | |

| 170 GPa | edge-wise in the width direction, ff(e) = 4099.0 Hz | ASTM E 1875, T = 600 °C | |

| 165 GPa | mean | ASTM E 1875, T = 650 °C | |

| 165 GPa | flat-wise in the thickness direction, ff(f) = 1385.0 Hz | ASTM E 1875, T = 650 °C | |

| 165 GPa | edge-wise in the width direction, ff(e) = 4052.0 Hz | ASTM E 1875, T = 650 °C | |

| 161 GPa | mean | ASTM E 1875, T = 700 °C | |

| 161 GPa | flat-wise in the thickness direction, ff(f) = 1367.0 Hz | ASTM E 1875, T = 700 °C | |

| 161 GPa | edge-wise in the width direction, ff(e) = 3994.0 Hz | ASTM E 1875, T = 700 °C | |

| 156 GPa | mean | ASTM E 1875, T = 750 °C | |

| 156 GPa | flat-wise in the thickness direction, ff(f) = 1346.0 Hz | ASTM E 1875, T = 750 °C | |

| 156 GPa | edge-wise in the width direction, ff(e) = 3932.0 Hz | ASTM E 1875, T = 750 °C | |

| 150 GPa | mean | ASTM E 1875, T = 800 °C | |

| 150 GPa | flat-wise in the thickness direction, ff(f) = 1322.0 Hz | ASTM E 1875, T = 800 °C | |

| 150 GPa | edge-wise in the width direction, ff(e) = 3863.0 Hz | ASTM E 1875, T = 800 °C | |

| Thermische Eigenschaften | |||

| linearer Längenausdehnungskoeffizient | 14.1 10⁻⁶/K | T = 100 °C | |

| 14.1 10⁻⁶/K | T = 200 °C | ||

| 14.2 10⁻⁶/K | T = 300 °C | ||

| 14.4 10⁻⁶/K | T = 400 °C | ||

| 14.8 10⁻⁶/K | T = 500 °C | ||

| 15.3 10⁻⁶/K | T = 600 °C | ||

| 15.85 10⁻⁶/K | T = 650 °C | ||

| 16.4 10⁻⁶/K | T = 700 °C | ||

| 16.7 10⁻⁶/K | T = 750 °C | ||

| 17 10⁻⁶/K | T = 800 °C | ||

Chemische Eigenschaften

53.7

17.82

18.26

5.21

3.02

0.93

0.53

0.16

0.14

0.08

0.04

Abbildungen und Diagramme

Daten bereitgestellt von

SLUB Dresden

- Birgit Rehmer, Faruk Bayram, Luis Alexander Ávila Calderón, Gunther Mohr, Birgit Skrotzki: Elastic modulus data for additively and conventionally manufactured variants of Ti-6Al-4V, IN718 and AISI 316 L. In: Scientific Data. Springer Science and Business Media LLC, 2023.

- Rehmer, B., Bayram, F., Ávila Calderón, L. A., Mohr, G., & Skrotzki, B. (2023). BAM reference data: Temperature-dependent Young's and shear modulus data for additively and conventionally manufactured variants of Ni-based alloy Inconel IN718 (1.0) [Data set]. Zenodo.

Material Hub-Team

Anfrage per E-Mail

Die BAM Referenzdaten wurden von der Bundesanstalt für Materialforschung und -prüfung (BAM) unter der Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/legalcode) auf Zenodo bereitgestellt.Die SLUB hat die bereitgestellten Inhalte einer Normalisierung unterzogen, die notwendig ist, um eine umfassende Recherche und die Vergleichbarkeit der Materialien zu ermöglichen. Trotz größter zumutbarer Sorgfalt können bei diesem Normalisierungsprozess Fehler auftreten, weshalb ausdrücklich darauf hingewiesen wird, dass auf Grundlage der im Material Hub vorhandenen Daten keine Entscheidungen zur Verwendung oder Anschaffung eines Materials getroffen werden dürfen. Vielmehr ist es notwendig den Datenerzeuger im Vorfeld einer solchen Entscheidung direkt zu kontaktieren, um die Korrektheit der Daten zu verifizieren.

Ähnliche Materialien

Wählen Sie die Materialeigenschaften aus, anhand derer ähnliche Materialien identifiziert werden sollen. Durch Hinzufügen weiterer Eigenschaften sowie Anpassen der jeweiligen Abweichung lässt sich die Ergebnisliste beeinflussen. Hier wird eine Auswahl der ähnlichsten Materialien angezeigt. Um die gesamte Liste zu erhalten, drücken Sie auf die Schaltfläche "Vollständige Ergebnisliste anzeigen".

.png)

.png)